The prerequisite for work was definition of requirements for novel energy system. First step, now completed, is the analysis of the technology readiness and screening of technologies available on the market. This analysis was led by EPFL partner (Ecole Polytechnique Fédérale de Lausanne). The core of the analysis was comparison of different energy conversion technologies and their hybridization supporting the onboard power supply of cruise ships, including existing individual technologies such as proton exchange membrane fuel cell (PEMFC), solid oxide fuel cell (SOFC) and battery (BAT), with the identification of main system indicators SOFC/PEMFC stack and system. Now the project is focusing on definition of market requirements, technical restrictions and regulatory constraints. This task should lead to definition of performance indicators of the most suitable system design.

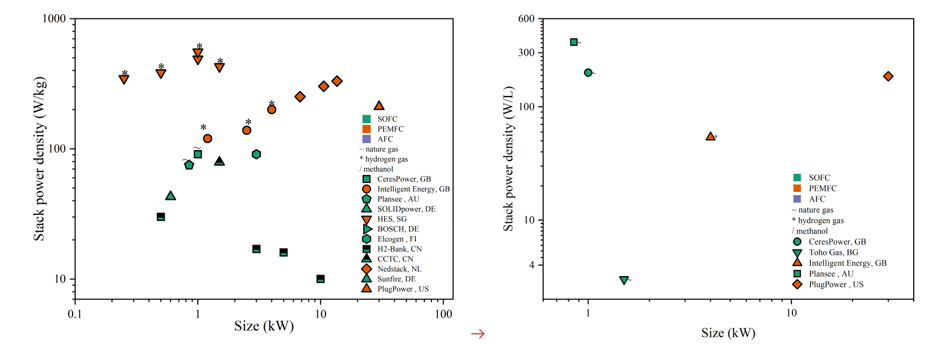

The Analysis findings for the SOFC/PEMFC stack

(Figure 1)

The capacity of single stacks is usually below several tens of kW. The PEMFC stacks can offer single stacks of 30 kW, while the maximum single-stack capacity of SOFC with power densities given is 10 kW. The SOFC stack mass power density is lower than that of the PEMFC stacks, since SOFC stacks are built with metal and ceramics components, while PEMFC stacks are composed of polymer membranes. The mass power density of SOFC stacks is usually below 100 W/kg, while the PEMFC stacks achieve the range of 100 – 600 W/kg. A limited data for volumetric power density is available for stacks. The volumetric power density of the SOFC stacks (200 – 400 W/L) can be higher than those of the PEMFC stacks (50 – 200 W/L).

Figure 1: Single stack power density comparison: mass (left), volumetric (right).

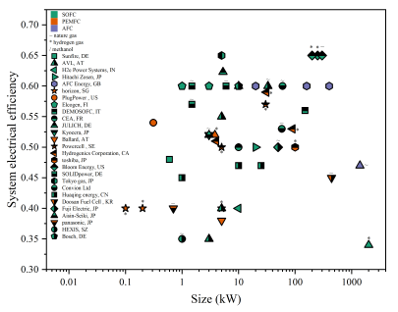

For SOFC/PEMFC system (Figure 2 and Figure 3), there have been products with a capacity of up to 300 kW – 1 MW. SOFC systems generally offer a capacity of over 1 kW, while a smaller capacity between tens of W and 1 kW is also commonly offered by PEMFC for, e.g., mobile applications. Large SOFC systems are currently mainly from US companies, particularly BloomEnergy. SOLIDpower has successfully tested a 25 kW large stack module. For system power density, the SOFC system power density is generally much lower than the PEMFC system power density, both in weight and volumetric power density. For mass system power density, the PEMFC systems achieve a higher value of 10-500 W/kg, while the SOFC systems generally offer a number below 70 W/kg. AVL and Sunfire offer a system power density of around 40 – 60 W/kg, while the SOLIDpower shows almost the least system power density (~ 5 W/kg).Similar observations have been applied to the volumetric system power density. The PEMFC systems offer a power density of 4 – 500 W/L, led by the Horizon and Hydrogenics (over 100 W/L). The SOFC systems offer lower volumetric power densities. The AVL shows a highly compact system design with the volumetric power density reaching 30 – 300 W/L, while other system providers offer a volumetric power density of below 10 W/L with the SOLIDpower systems offering a 4 – 6 W/L power density.

Figure 2: System power density: mass (left), volumetric (right).

For the system electrical efficiency, the SOFC systems show higher system electrical efficiency than the PEMFC systems. The PEMFC systems achieve system electrical efficiency of less than 60%, between 35 – 60%. Most products offer an electrical efficiency of 50 – 55%. The highest efficiency is achieved by the Hydrogenics and PowerCell, close to 60%. Most SOFC system electrical efficiency was above 45 – 60%. The companies in the highest tier system electrical efficiency include Tokyo gas, BloomEnergy, Aisin-Seiki, Elcogen, SOLIDpower, Bosch, AVL, and CEA. SOLIDpower offers a system electrical efficiency of 60%.

Figure 3: Technology comparison between SOFC and PEMFC in system electrical efficiency.

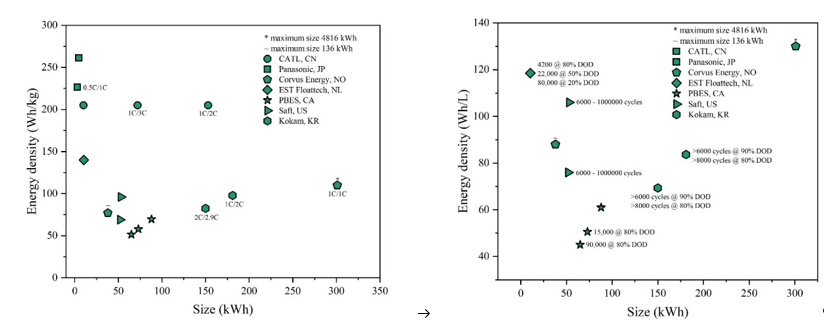

Battery

(Figure 4)

The size of single battery pack could be up to 300 kWh with the pack energy density within 50 – 270 Wh/kg and 40 – 120 Wh/L. The lifetime can drop significantly with the depth of discharge. At 80% depth of discharge, the tested lifetime can reach 90k cycles, achieved by PBES (CA). There has been lifetime of 1000k cycles but the working conditions are not given.

Figure 4: Comparison of battery packs in terms of mass (left) and volumetric (right) energy density.

SOFC-BAT Hybridization for maritime applications

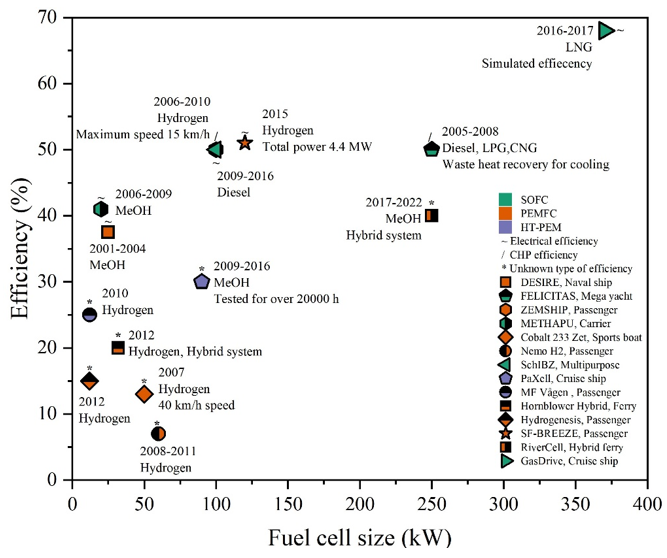

(Figure 5)

The sizes of FC in all demonstration projects are within 10 – 250 kW. However, compared with PEMFC-BAT hybrid system, only few detailed performance and techno-economic data are available for SOFC-BAT system. The capacity of 200 – 250 kW has been reported for both PEMFC and SOFC hybrid systems. The SOFC based projects have considered Diesel, LPG, CNG, MeOH as the logistic fuels, thanks to the high fuel flexibility of the SOFC technology. Particularly, none of these projects has investigated the potential of ammonia as the ship fuel. The SOFC demonstration occurred mostly ten years ago, with the CHP efficiency reaching only between 40 –50% due to the low SOFC system performance at that time. The recent SchIBZ project realized an electrical efficiency of 50%, the latest GasDrive project has reported a computed overall efficiency of 68%. Although most projects employed PEMFC based hybrid system due to the easy system configuration and dynamic performance, the SOFC based hybrid systems are potential for ship industry due to high efficiency and the possibility of heat and power co-generation.

Figure 5 Technology comparison of different FC-BAT hybrid system vessels.

Conclusions of the Analysis

PEMFC-BAT hybrid systems have been at high TRL for the transportation fields. However, they are constrained by the hydrogen infrastructure and onboard storage. SOFC can realize higher efficiency and combined heat and power production, thus is more suitable for the cases with less limitation in terms of space and weight, e.g., cruise ships. Below summarizes the main indicators for the SOFC systems or SOFC-BAT systems:

SOFC systems

| SOFC system mass power density (W/kg): | < 70 W/kg |

| SOFC system volumetric power density (W/L): | < 10 W/L |

| Lifetime (h, number of cycles): | SOFC generally known as long lifetime (40-80 kh) |

| Load range (%): | 30-125% (Bosch) |

| Startup/shutdown time (h): | 120-180 mins (Aisin-Seiki) |

| Ramp up/down rates (%/h): | 75% nominal load per hour |

| System electrical efficiency (%): | 45 – 60% |

| Emissions (GHG, NOx, SOx, PM): | |

| LGHG: | depends highly on fuel used |

| NOx: | 0.005–2 ppm |

| SOx: | - |

| PM: | < 0.09 mg/kWh (PM10) |

| Noise/vibration levels: | 40-70 dB (A) |

Battery packs

| Mass energy density: | 50-260 Wh/kg |

| Volumetric energy density: | 40-130 Wh/L |

| Lifetime depending strongly on operating conditions: | Generally, 6-90 k cycles @80%DOD |

SOFC hybrid systems for ship application

| Electrical efficiency: | 50% (lower than stationary SOFC systems) |

| Overall efficiency: | 77% with heat recovery |

| System design considerations: | anode off-gas recirculation, autothermal reformer, flexible switch of fuel |

Stay in touch with us!

#NAUTILUS_2020 #propulsionsystem #sustainableshipping #battery #fuelcell #cruiseships

***

⇒ Follow us on Twitter/LinkedIn to be on board.

Follow #NAUTILUS_2020

NAUTILUS is a short for Nautical Integrated Hybrid Energy System for Long-haul Cruise Ships.

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 861647.